Draeger Cylinders 4500 PSI

DRAGER

MSRP:

Now:

$1,040.00

(You save

)

- Availability:

- ships from manufacturer

- Shipping:

- Calculated at Checkout

Recommended

-

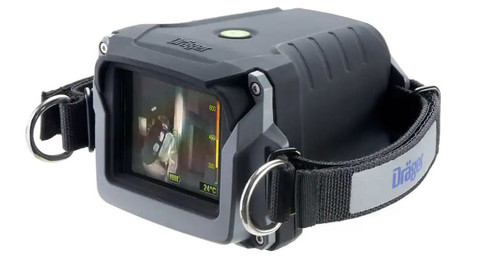

Draeger FireVista Thermal Imaging Camera Kit

MSRP:Now: $4,675.00Draeger PSS 5000 SCBA HP Quick Connect

MSRP:Now: $6,311.70